After MIG brazing collision repair, a comprehensive inspection is key. Technicians verify structural integrity through alignment testing using laser machines to confirm frame and component accuracy. Surface finish assessment ensures paint job perfection, hiding previous damage with seamless blending and matching vehicle specifications for a flawless, cosmetically superior result.

After successful MIG brazing collision repair, a meticulous inspection is crucial to ensure optimal results. This process involves three key steps:

– Visual Inspection: Carefully assessing visible damage and repair quality for seamless integration.

– Structural Integrity: Testing frame alignment and component stability to guarantee structural soundness.

– Surface Finish: Evaluating the paint job’s precision and perfection, ensuring a flawless finish.

Mastering these inspections ensures top-tier MIG brazing collision repair.

- Visual Inspection: Assessing Visible Damage and Repair Quality

- Structural Integrity: Testing Frame and Component Alignment

- Surface Finish: Evaluating Paint Job and Fitting Perfection

Visual Inspection: Assessing Visible Damage and Repair Quality

After MIG brazing collision repair is complete, a thorough visual inspection is crucial to assess both the visible damage and the quality of the repair. During this step, experienced technicians will meticulously examine the entire vehicle, paying close attention to the affected areas. They’ll look for any signs of remaining dents, scratches, or structural weaknesses that might have been missed during the initial repair process.

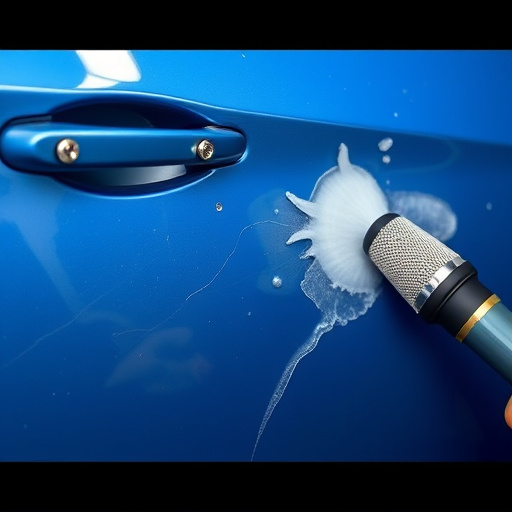

Visual inspection also involves evaluating the paint job and overall cosmetic appeal. This includes checking for even color application, proper blending with surrounding areas, and the absence of any bubbles, runs, or other defects in the car paint repair. By conducting a meticulous visual assessment, auto repair services can ensure that the MIG brazing collision repair meets high standards, delivering a vehicle that looks as good as new—with minimal to no visible evidence of the previous damage, effectively completing the transformation through car dent removal techniques.

Structural Integrity: Testing Frame and Component Alignment

After MIG brazing collision repair is complete, it’s crucial to verify the structural integrity of the vehicle. This involves testing the alignment of the frame and components to ensure they are in perfect harmony and function as intended before the collision. By examining the fit and finish of panels, technicians can identify any misalignments or gaps that may indicate underlying issues. Using specialized tools, such as laser alignment machines, can help measure and adjust these parameters precisely.

This meticulous process goes beyond mere cosmetic repairs like car scratch repair or vehicle dent repair; it ensures the safety and reliability of the vehicle. Proper frame and component alignment is vital for maintaining optimal handling, braking performance, and overall stability during driving. Thus, it’s essential to confirm that every piece is in its rightful place before considering the job truly finished.

Surface Finish: Evaluating Paint Job and Fitting Perfection

After successful MIG brazing collision repair, one of the critical aspects to assess is the surface finish. The paint job and overall fitting perfection are indicators of the quality of the repair work. Upon completion, inspect the affected area for any visible imperfections such as brush strokes, uneven painting, or spots where the paint didn’t adhere properly. A professional automotive body shop will strive for a seamless blend that matches the car’s original finish, making it challenging to discern the repaired area from the rest of the vehicle.

A meticulous assessment includes verifying the paint’s gloss and texture, ensuring they align with the vehicle’s original specifications. The repair should not leave any visible evidence of the previous collision damage, like dents or scratches, which could compromise the car’s aesthetic appeal. Achieving a flawless finish requires skilled technicians who understand the intricacies of car dent repair and know how to address automotive body shop challenges to deliver exceptional results.

After completing a MIG brazing collision repair, a thorough inspection is vital to ensure optimal results. By conducting a visual assessment, checking structural integrity, and evaluating the surface finish, you can verify the quality of the repair work. These steps are essential for ensuring that the vehicle not only looks good but also maintains its structural soundness and safety standards. Incorporating these inspections into your post-repair process guarantees a successful MIG brazing collision repair job.