MIG brazing collision repair is a cutting-edge technique using a metal inert gas (MIG) welding gun to precisely repair high-strength steel vehicle components, minimizing porosity and maximizing structural integrity. This method offers enhanced repair quality, faster turnaround times, and extended vehicle lifespans, making it a game-changer in the automotive repair sector. While demanding meticulous preparation and precise technique, MIG brazing delivers seamless, aesthetically pleasing repairs that match original specifications, streamlining the process for automotive professionals.

In the realm of automotive collision repair, advancements in materials science have introduced high-strength steel (HSS) panels as game-changers. Among the techniques facilitating their efficient utilization is MIG brazing—a powerful and precise method for rejoining metal components. This article delves into the intricacies of MIG brazing collision repair specifically tailored for HSS panels, exploring its advantages and providing a comprehensive step-by-step guide to ensure optimal results.

- Understanding MIG Brazing: A Powerful Technique for Collision Repair

- The Advantages of Using High-Strength Steel Panels in Collision Repair

- Step-by-Step Guide: Effectively Performing MIG Brazing on Collison-Damaged Vehicles

Understanding MIG Brazing: A Powerful Technique for Collision Repair

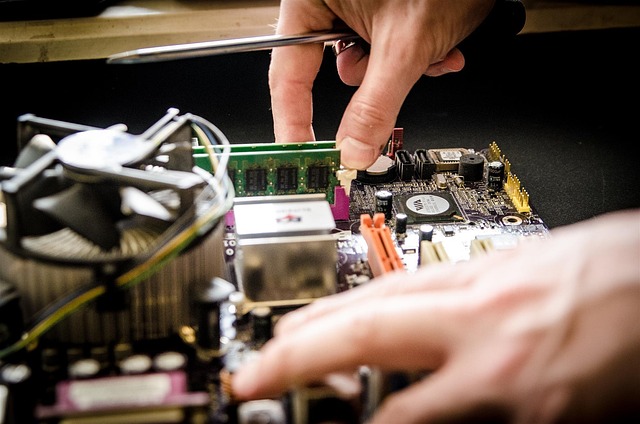

MIG brazing collision repair is a specialized technique that has revolutionized the automotive repair industry, particularly for high-strength steel panels. This powerful method involves using a metal inert gas (MIG) welding gun to join and repair damaged components with remarkable precision and strength. Unlike traditional welding techniques, MIG brazing offers a clean, controlled environment by shielding the weld area from oxygen, which minimizes porosity and weak spots in the final joint.

This advanced approach is especially beneficial for auto body services and car repair services dealing with modern high-strength steel vehicles. By employing MIG brazing, skilled technicians can precisely restore damaged panels to their original specifications, ensuring structural integrity and a seamless finish. This not only enhances the overall quality of collision repair but also extends the lifespan of vehicles, making it an indispensable tool in the automotive repair sector.

The Advantages of Using High-Strength Steel Panels in Collision Repair

High-Strength Steel Panels offer numerous advantages when it comes to MIG brazing collision repair. Firstly, their superior structural integrity ensures that repaired areas are stronger than ever before, enhancing the overall durability of vehicles. This is particularly beneficial for auto body work involving complex or critical components, where strength and stability are paramount.

Moreover, these panels facilitate precise and efficient auto collision repair processes. Their consistent material properties allow for more accurate welds using MIG brazing techniques, resulting in cleaner, more professional-looking repairs at the auto body shop. This not only reduces the time required for repairs but also enhances the aesthetic appeal of the final product, making them a preferred choice among automotive professionals for top-quality auto body work.

Step-by-Step Guide: Effectively Performing MIG Brazing on Collison-Damaged Vehicles

Performing MIG brazing on collision-damaged vehicles requires precision and a step-by-step approach to ensure structural integrity and aesthetic appeal. Here’s a guide for effective MIG brazing collision repair:

1. Preparation: Begin by thoroughly cleaning and inspecting the damaged area. Remove any debris, rust, or loose material. Ensure proper ventilation in the auto bodywork shop as brazing involves intense heat. Prepare your tools, including the MIG welder, wire feed system, shielding gas cylinders, and brazing rods specific to high-strength steel.

2. Welding Technique: Position the MIG welder correctly, maintaining a steady arc length. Adjust the welding current and voltage settings according to the metal type and thickness. Start welding at a non-visible area to practice the technique and ensure a consistent bead. For collision repair, focus on matching the existing metal’s contour and color as closely as possible. Use a shielding gas that suits high-strength steel brazing, typically a mixture of argon and carbon dioxide, to protect against oxidation.

MIG brazing collision repair offers a highly effective and efficient solution for restoring damaged vehicles, particularly with high-strength steel panels. By understanding the technique and its advantages, as outlined in this article, body shops can provide top-quality repairs that are both durable and aesthetically pleasing. Following the step-by-step guide ensures precision and consistency, making MIG brazing a valuable skill for any collision repair professional.